Turbo wastegates are critical components in turbocharged engines, controlling exhaust gas flow to reduce backpressure and improve turbo response times. This optimization enhances engine power and performance while strategically complementing safety features like brakes and suspension for smoother deceleration. Modern advancements in design, using materials like titanium and high-strength alloys, enable weight reduction without compromising structural integrity, and precise engineering ensures quicker valve actuation, preventing overboosting for reliable and safer driving experiences.

A turbo wastegate is a crucial component in turbocharged engines, regulating exhaust gas flow to enhance power delivery and overall engine performance. This article delves into the fundamental principles of turbo wastegates, exploring how they optimize power output while ensuring safety. We examine modern innovations that have made these components more efficient, reliable, and responsive, ultimately improving driving experience. Understanding the role of a turbo wastegate offers insights into the cutting-edge technologies shaping the automotive industry.

- Understanding Turbo Wastegates: The Basic Principles

- How Turbo Wastegates Enhance Power Delivery

- Safety Considerations and Modern Innovations in Turbo Wastegate Design

Understanding Turbo Wastegates: The Basic Principles

Turbo Wastegates: Unlocking Enhanced Performance and Safety

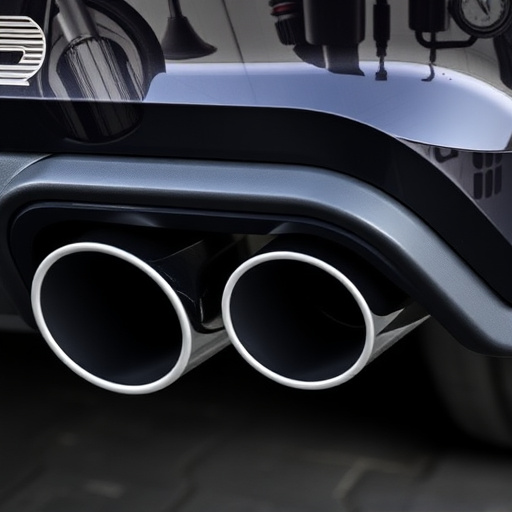

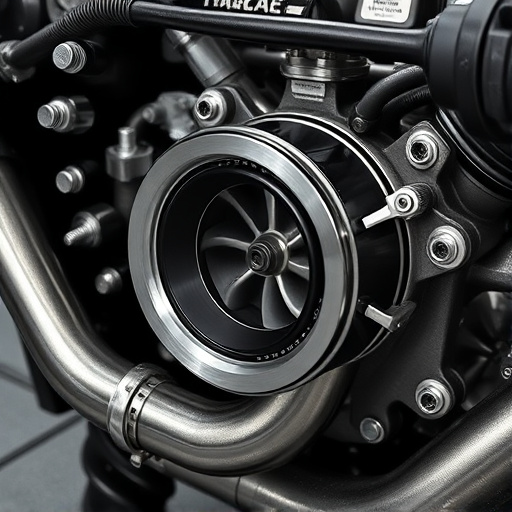

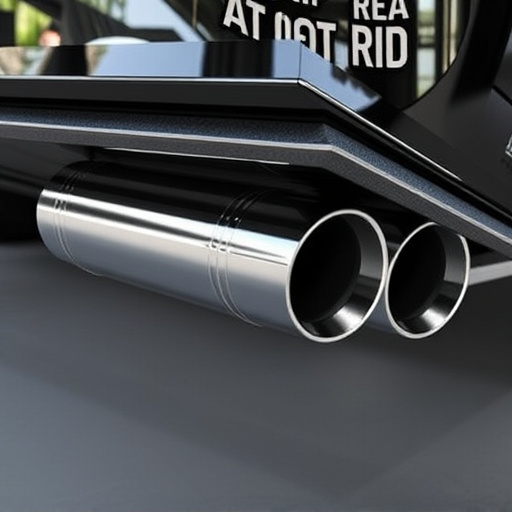

A turbo wastegate is a critical component in turbocharged engines, allowing for precise control over exhaust gas flow. It functions as a valve that selectively routes exhaust gases around the turbocharger when certain conditions are met. This technology enables the engine to maintain optimal efficiency and power output across various driving scenarios. When engaged, the wastegate redirects exhaust gases, reducing backpressure and enabling faster response times from the turbocharger. This direct connection ensures that fresh air can continuously enter the combustion chamber, fueling efficient burning and enhancing overall performance.

Moreover, the strategic implementation of turbo wastegates enhances safety features like performance brakes and robust brake rotors, often bolstered by advanced suspension kits. By efficiently managing exhaust gases, it contributes to smoother deceleration and improved control during high-performance driving, making it a key enabler for enhanced vehicle dynamics.

How Turbo Wastegates Enhance Power Delivery

Turbo Wastegates play a pivotal role in enhancing power delivery in vehicles equipped with turbochargers. By efficiently controlling the flow of exhaust gases, they optimize the amount of air and fuel entering the engine, leading to increased combustion efficiency. This direct correlation between exhaust systems and power output results in a more responsive and powerful vehicle performance. When combined with high-performance parts like advanced turbochargers and precise fuel injection systems, the impact on acceleration and top-end speed is significant.

Moreover, effective wastegate management contributes to improved safety features. Modern turbo wastegates incorporate sophisticated mechanisms to quickly regulate engine pressure, enhancing drivability and stability. This precision engineering ensures that the vehicle responds swiftly to driver inputs, providing better control and reducing the risk of wheel spin or loss of traction—particularly beneficial during aggressive driving or in challenging weather conditions where brake rotors may be subjected to heightened stress.

Safety Considerations and Modern Innovations in Turbo Wastegate Design

In recent years, modern innovations in turbo wastegate design have led to significant advancements in both vehicle performance and safety considerations. The traditional wastegate, while effective for basic engine management, often falls short in meeting the stringent demands of contemporary automotive systems. As such, engineers have focused on enhancing the turbo wastegate’s capabilities to improve overall vehicle dynamics.

One key aspect of these innovations is the integration of advanced materials and manufacturing techniques. Modern turbo wastegates are crafted from lightweight, yet robust materials like titanium and high-strength alloys, ensuring optimal weight reduction without compromising structural integrity. Additionally, precise engineering and computer-aided design have resulted in more efficient valve actuation systems, enabling quicker response times. This not only enhances vehicle performance by optimizing gas flow but also plays a crucial role in safety. Quick valve adjustments can help prevent engine overboosting, a condition that could lead to potential damage or accidents. Moreover, these advancements contribute to the overall reliability of exhaust systems, including intake components and exhaust mufflers, ensuring a smoother driving experience for users.

The turbo wastegate, through its ability to control exhaust gas flow and regulate boost pressure, plays a pivotal role in enhancing engine performance and safety. By optimizing power delivery, these systems contribute to improved throttle response and fuel efficiency. Moreover, modern innovations have addressed safety concerns, making turbo wastegates more reliable and durable. As technology advances, continued focus on refining their design will further benefit the automotive industry, ensuring better engine performance and enhanced driver experiences.