The turbo wastegate is a vital component in both gasoline and diesel turbo systems, managing exhaust gas flow to optimize boost pressure, engine power, and torque. It offers benefits like improved fuel economy, reduced emissions, and smoother power delivery. For optimal performance, regular maintenance including inspections and timely part replacements is crucial, focusing on seal, gasket, and bearing condition. Upgrading to modern components enhances valve responsiveness and control, resulting in better engine response and reduced turbine backpressure. Always choose compatible, durable parts for sustained efficiency.

“Unleash the power of turbocharged engines with a deeper look into the critical component, the turbo wastegate. This essential mechanism plays a pivotal role in enhancing performance across both gasoline and diesel systems. From optimizing exhaust gas flow to ensuring efficient boost pressure, understanding the turbo wastegate’s function is key to maximizing engine output. We’ll explore its benefits, dissect applications in gasoline and diesel engines, and provide insights on maintenance and upgrades for peak performance.”

- Understanding Turbo Wastegates: Function and Benefits

- Gasoline vs. Diesel: Applications and Differences

- Maintenance and Upgrades for Optimal Performance

Understanding Turbo Wastegates: Function and Benefits

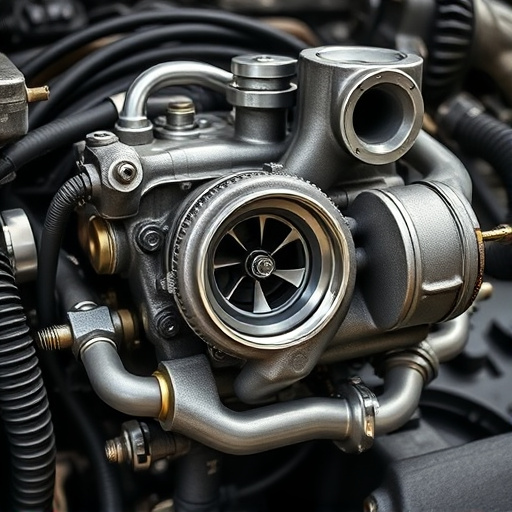

A turbo wastegate is a vital component in both gasoline and diesel turbo systems, enabling efficient engine performance. Its primary function is to control the flow of exhaust gases from the turbine to the muffler tips or exhaust tips, thereby regulating turbocharger boost pressure. By doing so, it ensures that the turbocharger spins at optimal speeds, enhancing engine power and torque output.

The benefits of a well-functioning turbo wastegate are numerous. It allows for better fuel economy by preventing excessive compression, which can lead to knock or detonation in the cylinder. Moreover, it contributes to reduced emissions, as it helps maintain a balanced combustion process. In addition, turbo wastegates provide smoother power delivery and improved throttle response, enhancing both driving pleasure and engine efficiency, especially when paired with coilover kits for fine-tuned control.

Gasoline vs. Diesel: Applications and Differences

In the realm of turbocharged engines, whether gasoline or diesel, the turbo wastegate plays a pivotal role in optimizing performance and efficiency. Gasoline-powered vehicles often employ turbochargers to enhance power outputs, particularly in higher RPM ranges. Here, the turbo wastegate directs exhaust gases from the combustion chamber, allowing for faster turbine rotation and improved charging efficiency. This direct injection of compressed air results in heightened engine performance, making gasoline turbo systems ideal for sports cars and high-performance vehicles.

On the other hand, diesel engines utilize turbocharged technology to improve torque delivery at lower RPMs, ensuring smoother acceleration and better fuel economy. Unlike gasoline, diesel exhaust systems incorporate a complex network of sensors and controls to manage the turbo wastegate. This results in precise regulation of exhaust gas flow, enabling optimized combustion and enhanced overall engine performance. The differences in application stem from the inherent characteristics of gasoline and diesel fuels, leading to distinct challenges and advantages when it comes to turbo wastegate design and functionality.

Maintenance and Upgrades for Optimal Performance

Regular maintenance is key to keeping a turbo wastegate functioning at its best, ensuring optimal performance for your gasoline or diesel turbo system. This includes periodic inspections and checks for any signs of wear and tear, as well as timely replacements of worn-out parts. The wastegate, being a critical component in regulating exhaust gas flow, requires meticulous care. Regular servicing involves verifying the condition of seals, gaskets, and bearings, as these are prone to damage due to extreme temperatures and pressures.

Upgrading your turbo wastegate can further enhance performance. Modern upgrades often focus on improving the valve’s responsiveness and precision control. These enhancements ensure efficient wastegate opening and closing, allowing for better engine response and reduced turbine backpressure. When considering upgrades, it’s essential to choose components that are compatible with your specific turbo system, focusing on products designed for durability and reliability, just like high-quality brake pads or intake components.

A turbo wastegate is a vital component in both gasoline and diesel turbo systems, enhancing performance by efficiently controlling exhaust flow. By understanding its function and benefits, as well as the distinct applications for gasoline and diesel engines, you can ensure optimal performance through proper maintenance and potential upgrades. Incorporating these insights into your knowledge base allows you to navigate the world of turbochargers with expertise, making informed decisions to harness the full potential of your vehicle’s engine.