A turbo wastegate, a crucial component in turbocharged engines, optimizes performance and efficiency by controlling exhaust gas flow. Its diaphragm separates high-pressure zones from low-pressure areas, enabling the valve to open for reduced backpressure and faster turbine rotation. Springs provide resistance for precise regulation during demanding conditions, enhancing durability and reliability of the mechanism and protecting other components from heat and pressure damage. The sophisticated valve and spring system ensures efficient energy transfer while minimizing backpressure, contributing to a superior driving experience.

“Unleash the power of your engine with a deeper dive into the intricate world of the turbo wastegate. This essential component, comprising specific parts like diaphragms, valves, and spring mechanisms, plays a pivotal role in enhancing turbine efficiency.

In this article, we’ll explore the crucial functions of each element, revealing how they work harmoniously to optimize engine performance. From understanding basic components to examining the diaphragm’s critical role and precise control through the valve and spring, you’ll gain valuable insights into turbo wastegate technology.”

- Understanding Turbo Wastegate Components

- Diaphragm's Role in Wastegate Operation

- Valve and Spring: Ensuring Precise Control

Understanding Turbo Wastegate Components

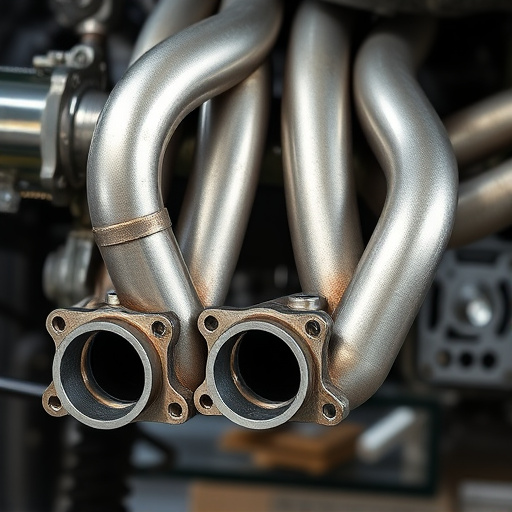

A turbo wastegate is a vital component within turbocharged engines, playing a crucial role in optimizing performance and efficiency. Its primary function is to control the flow of exhaust gases, allowing for precise timing and pressure regulation. This mechanism consists of several key parts that work harmoniously. The diaphragm, often made from durable materials like metal or composite, acts as a flexible barrier that responds to changes in pressure. It separates the turbocharger’s high-pressure zone from the low-pressure area of the exhaust system.

The valve, typically controlled by an actuator, opens and closes in response to engine conditions. When the diaphragm is pushed by increasing exhaust gas pressure, it activates the valve, diverting a portion of the exhaust flow away from the turbocharger. This process reduces backpressure, enabling the turbine to spin faster and boost power output. Additionally, springs within the mechanism help maintain control by providing resistance against the diaphragm’s movement, ensuring precise regulation during high-performance situations, such as when installing a performance exhaust system or modifying exhaust mufflers.

Diaphragm's Role in Wastegate Operation

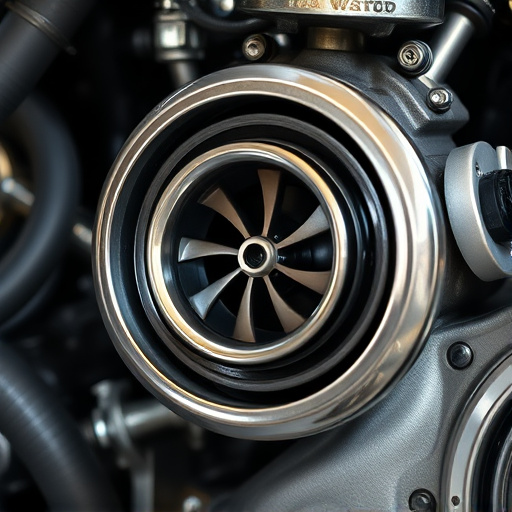

The diaphragm plays a pivotal role in the smooth operation of a turbo wastegate. Acting as a flexible barrier, it separates the high-pressure air from the low-pressure side of the turbocharger. When the engine demands more power, the diaphragm flexes to allow increased flow of exhaust gases through the valve, thus boosting turbine speed and compressing intake air for greater efficiency. This dynamic movement ensures precise control over the turbo’s performance, preventing excess boost and maintaining optimal engine output.

Moreover, the diaphragm’s design contributes to the overall durability and reliability of the turbo wastegate system. By mitigating direct exposure to high-pressure exhaust, it protects other suspension components—such as the valve and spring mechanism—from potential damage caused by heat and pressure. This protection extends the lifespan not only of the wastegate but also of related parts like brake pads in performance vehicles, ensuring that drivers enjoy consistent power delivery and controlled driving dynamics.

Valve and Spring: Ensuring Precise Control

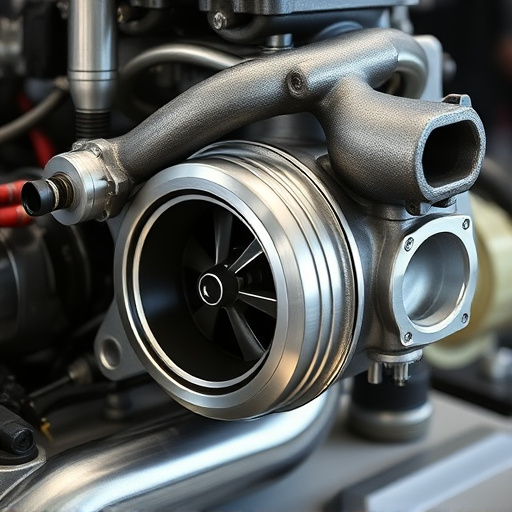

The heart of a turbo wastegate lies in its intricate valve and spring mechanism. This component plays a pivotal role in regulating the flow of exhaust gases from the engine, ensuring precise control over the turbocharger’s boost. The valve, typically crafted from robust materials, opens and closes in response to pressure differentials, allowing for efficient energy transfer while minimizing backpressure.

Accompanying this is a carefully designed spring system that exerts controlled force on the valve. The interplay between the spring tension and exhaust gas pressure facilitates smooth and accurate control of turbocharger operation. This intricate arrangement not only optimizes engine performance but also contributes to enhancing overall vehicle dynamics, especially when paired with high-performance exhaust systems and air filters, making it a key factor in achieving superior driving experiences, even when braking rotors demand intense stopping power.

A well-functioning turbo wastegate, composed of a diaphragm, valve, and spring mechanism, is pivotal to optimal engine performance. By understanding each component’s role—from the diaphragm’s pressure regulation to the precise control of the valve and spring—we can appreciate how these parts collaborate to enhance power output and efficiency in vehicles equipped with turbocharged engines. This knowledge highlights the significance of regular maintenance and high-quality components for ensuring the longevity and reliability of a turbo wastegate system.